charpy v notch impact test astm|charpy impact test diagram : chain store Standards. • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials. Purpose. • To determine the energy required to fracture a v-notched specimen. This energy . webООО Яндекс, ОГРН 1027700229193, Россия, г. Москва, ул. Льва Толстого, д. 16, 119021. Direct Cursus Technology L.L.C, UAE, Dubai, Al Barsha First, AL KHAIMAH BUILDING II, office No. 3F-78 F. Foydalanuvchi bilan kelishuv Maxfiylik siyosati Texnik yordam. undefined dasturchining barcha o‘yinlari .

{plog:ftitle_list}

web11 de set. de 2019 · 2:04. I. A Seguir. For All Mankind 1ª Temporada Trailer Original. adorocinema. 1:13:13. 1ª-2y3. Sagrada Familia Capítulo 2 y 3 - 1ª Temporada. (Serie Española) NETFLIX 2022-3.

The robotic testing system roboTest I supports the user in the performance of Charpy impact tests to ISO 148-1 or ASTM E23. The system can be used to automatically test up to 450 notched metal specimens in a temperature range .

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the .

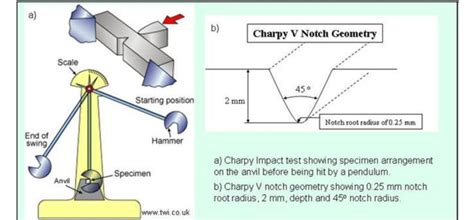

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .The apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the material can be inferred by comparing the difference in the height of the hammer before and after the fracture (energy absorbed by the fracture event).Standards. • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials. Purpose. • To determine the energy required to fracture a v-notched specimen. This energy .Charpy Impact Test ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the .

charpy v notch toughness

Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy .

5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or .Engineers and researchers who have specialized Charpy testing needs will be the primary users of two new standards recently approved by ASTM International Committee E28 on Mechanical Testing. The new standards, E2248, Test Method for Impact Testing of Miniaturized Charpy V-Notch Specimens, and E2298, Test Method for Instrumented Impact Testing of Metallic .

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations . The impact tests employed in the research work were the Charpy V-notch impact test and the drop-weight tear test (DWTT). The impact tests have been correlated with full-size cylindrical vessel tests in which the initiation and propagation characteristics have been determined under controlled conditions.

charpy v notch testing standard

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. . For example, when testing steel for use in cold climates, the ASTM A370 Charpy impact test can reveal how the material’s toughness decreases as temperatures drop. This information is vital .

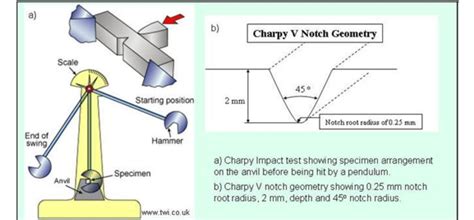

Since 2016, ASTM E23 covers Charpy strikers having an edge radius of 8 mm (as in the past) and 2 mm (previously only covered by ISO 148:2). . We also provide two SRMs that are used to verify the measurement of maximum force in a Charpy impact test, and SRMs for the verification of small-scale impact machines (miniaturized Charpy specimens). .At WMT&R, Izod and Charpy impact testing are performed on instrumented machines capable of measuring less than 1 foot-pound to 300 foot pounds at temperatures ranging from -320°F to over 2000°F. Impact test specimen types include notch configurations such as V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) V-Notch, with capabilities of . Engineering Fracture Mechanics Vol. 32,No. 1, pp. 39-42,1989 0013-7944/89 .00-1-.00 Printed in Great Britain 1989 Pergamon Press pic. CHARPY V-NOTCH IMPACT TEST: A PARTIAL ALTERNATE TO ASTM E 399 FRACTURE TESTING FOR ROUTINE QUALITY CONTROL APPLICATIONS B. NAGESWARA RAO and A. R. ACHARYA Structural . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

charpy v notch testing requirements

ASTM E23 Charpy Impact Tests. STM and ISO Charpy V Notch Tests utilize the same test specimen, but are tested on different machines and calibrated to different agency reference standards. ASTM is an acronym for the American Society for Testing and Materials.For the assessment of material toughness, international standards commonly require Charpy V-notch (CVN) impact testing of the steel product. . in order to have enough cross-sectional area for impact testing (ASTM 2009). On the other hand, for thick-walled HSS where full-sized CVN specimens are possible, ASTM A370 permits the notch to be .

Charpy V-notch (CVN) impact-test results are used widely in various toughness specifications even though the energy absorption values cannot be related directly to structural design. Conversely, K Ic , the plane-strain stress-intensity factor at onset of unstable crack growth, can be related to structural design, but K Ic test results usually . The instrumented impact test with Charpy specimens of subsize geometry is discussed in relation to equivalent standard procedures for performing the test with specimens of regular size. Subsize specimens because of their smaller dimensions imply smaller load values and higher frequencies of the force oscillations.

They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations (see Annex A3), precracking Charpy V-notch specimens (see Annex A4), designation of test specimen orientation (see Annex A5), and determining the .

Four types of impact testing are described in detail below, encompassing the pendulum, drop-weight, and dynamic tear methods: 1. Charpy. The Charpy impact test, also known as the V-notch test, is a type of impact . Standard Test Method for Impact Testing of Miniaturized Charpy V-Notch Specimens E2248-12 ASTM|E2248-12|en-US Standard Test Method for Impact Testing of Miniaturized Charpy V-Notch Specimens Standard E2248 Standard Test Method for Impact Testing of Miniaturized Charpy V-Notch Specimens> new BOS Vol. 03.01 Committee E28 $ .• ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials Purpose • To determine the energy required to fracture a v-notched specimen. This energy translates into the toughness of the material. Equipment and Materials • Charpy V-notch impact testing machine (figure 1.3.1) • Specimens: 1018 CR steel & 6061-T6 aluminum .The Certification of Two New Master Batches of V-Notch Charpy Impact Toughness Specimens in Accordance with EN 10045-2: 1992 . Pendulum Impact Testing: A Century of Progress, ASTM STP 1380, Seattle, Washington, ASTM International, West Conshohocken, PA, 2000. Google Scholar.

a strong negative influence on the impact energy measured through Charpy V-Notch testing. It was not possible to model more complicated steel alloys. This was due to the different precipitation processes being utilized for other grades. A514 uses Nb, V and/or Ti to form carbides and fine grain sizes. Without bringing in the processing .Evaluation of Fabrication Method for Making Notches for Charpy V-Notch Impact Specimens . RD Koester, SE Barcus. Quantitative Comparison and Evaluation of Various Notch Machining Methods and How They Affect ASTM E23 and ISO R442 Testing Equipment Results . DA Fink. The Effect of Fatigue Pre-Cracking Versus V-Notching on Impact Testing of Charpy . 1.2 This standard concerns Miniaturized Charpy V-Notch specimens, for which all linear dimensions, including length and notch depth, are reduced with respect to a type A standard impact test specimen in accordance with Test Methods E23.These are not the same as sub-size specimens, described in Annex A3 of Test Methods E23, for which length, notch .and Charpy V-notch impact testing is typically only performed when required in the contract documents. Generally, ASTM standards contain supplemental require-ments related to Charpy testing. Testing to other toughness requirements is also possible. Some materials, like A913, have toughness requirements in the standard and supplemental

charpy v notch test procedure

Charpy V-Notch Impact Test for Group 4 and 5 Structural Shapes SX3.1 When Group 4 and 5 structural shapes are used as members subject to primary tensile stress and when such members are spliced using full penetration welds, the steel shall be impact tested in accordance withESIS TC5, “Proposed Standard Method for Instrumented Impact Testing of Sub-Size Charpy V-Notch Specimens of Steels” (Annex C), Draft 10a, 23/5/02 [10] Lucon E., Round-Robin On Instrumented Impact Testing Of Sub Size Charpy-V Specimens: Results Of Phase 1”, ESIS TC5 Instrumented Impact Testing, Final Report, 2 April 1998 [11]

A Charpy impact test, also known as the Charpy V-notch test, is a destructive method designed to measure the amount of energy that a material can absorb as it fractures. . ASTM A327, ASTM A370, ASTM A673, ASTM D256, ASTM D2164, ASTM D2794, ASTM D3763, ASTM D5420, ASTM D5628, ASTM E 23, ASTM E1007, ASTM E1803, ASTM E1886, ASTM .

The impact tests employed in the research work were the Charpy V-notch impact test and the drop-weight tear test (DWTT). The impact tests have been correlated with full-size cylindrical vessel tests in which the initiation and propagation characteristics have been determined under controlled conditions.Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.

charpy v notch sample size

charpy impact test sample dimensions

8 de ago. de 2023 · ️⚧️ | gaúcha | 刺 ️ Conteúdo exclusivo . 35K Followers.

charpy v notch impact test astm|charpy impact test diagram